TerraPerforma

- 3D Printed Performative Wall

The project TerraPerforma focuses on large scale 3D printing, the influence of additive manufacturing on building with a traditional material – unfired clay – and climatic performative design

Mud construction is an ancestral technique found worldwide, with an ecological footprint close to zero. Mud/ clay, due to its thermal inertia properties, allows significant winter heating and summer cooling. It also offers a self-regulating humid environment, due to its ability to absorb and evaporate moisture, promoting healthy indoor climate. Though the benefits of clay construction in vernacular architecture are recognised for thousands of years, today, it faces the stigma of being traditional or primitive method, associated with under-developed regions of the world. The aim of this project is to develop a modern architectural prototype for clay construction with contemporary technology.

The project combines three various postures of 3D Printing – Robotic fabrication, On-Site Printing and Printing with Clay, examples of which have been studied while developing the TerraPerforma Project.

Though 3D printing can create complex geometries, the TerraPerforma design show-cases an easier method to create performative shapes through optimization strategies.

During TerraPerforma, different tests were carried out to explore the possibilities to optimise the design in accordance with various performance parameters. The project was developed by researching climatic phenomena and material behaviour. A series of physical tests and digital simulations were carried out for wall prototype with respect to solar radiation; day-light; thermal conductivity, convection & mass; and Structural Behavior. RHINO CFD, Ladybug, Karamba Softwares were used to simulate wind, sun and structural behaviour. The team also developed machines, such as Hygrothermal Monitoring Apparatus and the Load Machine, to pursue further studies, and also a light visualization exercise by recreating sun path with the help of the robot.

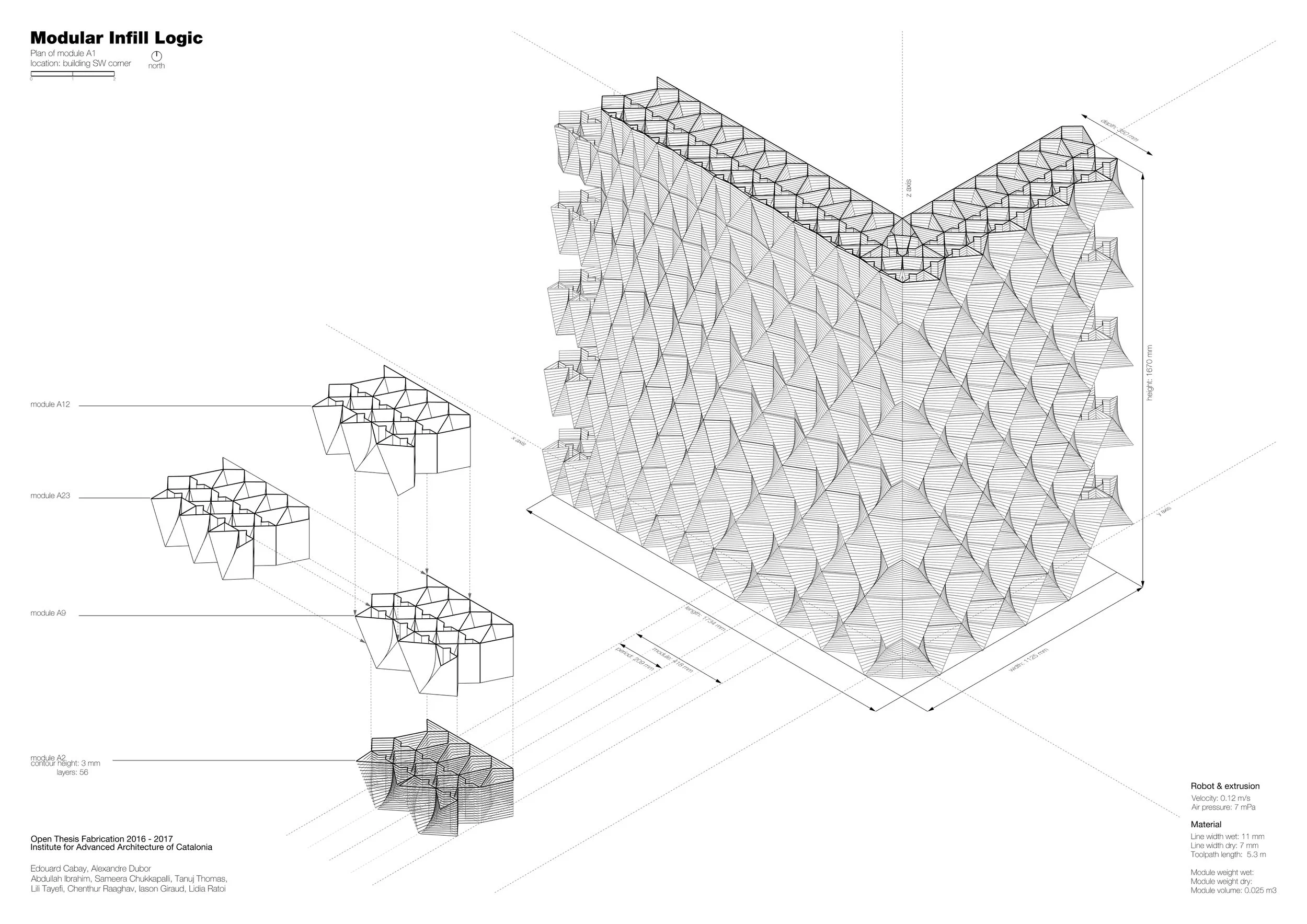

A modular approach was adopted in developing the final prototype of TerraPerforma, due to the difficulties of bringing a robot in the outdoor and hard climatic conditions. The modules are parametrically conceived so that they have optimum performance with regard to solar radiation, wind behaviour and structural 3D printing reasoning, both on their own and as a whole design. The façade was conceived as a gradient in both horizontal and vertical directions, having various radii of self-shading, in order to optimize east and west sun.

The wall module is designed with openings, from micro-perforation to full-openings between bricks. The wall-openings are strategically placed to harness the natural daylight potential. The full-openings work as light channels in addition to aiding in wind behaviour through convection properties while the micro-perforation directs the air flow.

Project Credits

Program Directors: Edouard Cabay, Alexandre Dubor.

Research Advisors: Areti Markopoulou, Mathilde Marengo, Rodrigo Aguirre, Angelos Chronis, Sofoklis Giannakopolous, Djordje Stanojevic, Kunaljit Singh Chadha, Ji Won Jun, Angel Munez, Manja Van De Warp, Wilfredo Carazas Aedo, Josep Perello, Pierre-Elie Herve, Jean-Baptiste Izard, Gregoire Durrens, Jonathan Minchin.

Researchers: Sameera Chukkappali, Iason Giraud, Abdullah Ibrahim, Raaghav Chentur Naagendran, Lidia Ratoi, Lili Tayefi ,Tanuj Thomas.