RESPONSE_ABLE

“ architecture has always wanted more –to be one of us, self-aware, pulsing with life; it has always sought to mimic the living”

-Living Bits and Bricks, Alex Haw, Carlo Ratti, AR, May 2012

Our objective in this project is to create dynamic relationships between structure, environment and man, by adopting new technologies and smart materials in our design. Our goal is to find an equilibrium where digital concepts intertwine with physical structures and how these structures in turn can enhance the environment as well as human perception and activity.

In this project, we considered the mechanisms of kinetics in an environmental and human responsive structure where smart materials are completely embedded. We introduced Shape Memory Polymer for the case study of smart materials. We are looking for a programmed surface which reacts to wind and human decisions; an interface system which stores real time local wind data and proposes optimum surface transformations for ventilation of space. The user is able to choose the shape and the form of transformation and also set his own needs so the system would propose new solutions.

SMPs possess two material phases- glass and rubber. In the glass phase, the material is rigid and cannot be easily deformed. When the temperature is greater than “Glass transition temperature”, the material enters the soft rubber phase and becomes easily deformable. SMP recovers by heating the material above its glass transition temperature. In the glassy state all movements of the polymer segments are frozen. The transition to the rubber-elastic state occurs upon increasing the thermal activation, which means that the rotation around the segment bonds becomes increasingly unimpeded. In this elastic state, a polymer with sufficient molecular weight stretches in the direction of an applied external force. If the stress is applied for a short period of time, the entanglement of the polymer chains with their direct neighbours will prevent a large movement of the chain. So when the external stress is released, the sample recovers to its original length. If the stress is applied for a longer period of time, then a relaxation process will take place which results in a plastic, irreversible deformation of the sample because of slipping and disentangling of the polymer chains from each other.

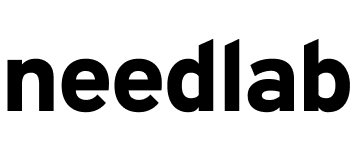

SMP can be activated by temperature, pH or light. In this project, we focused on temperature as it is the most appropriate method for this specific polymer. In our initial experiments, we used heatgun; but it couldn’t offer a continuous, uniform stream of hot air. Next, we used Nichrome wire, an alloy commonly used in heating devices, which gets heated up when electrical power is supplied. As the current travels through the nichrome wire, the resistance creates a voltage drop and, in turn, heat (P = 12 *R). We coiled nichrome wire (0.03mm) around the SMP to get uniform and precise heat. The length and thickness of the wire depend up on the size of the SMP. The distance between coiling depends on the extent of deformation needed.

Actuators are characterized as the forces which deform the SMP after it gets heated and becomes flexible. There are multiple ways to change SMP’s shape; for this project we deformed the SMP by hand, by pulling with strings and by using soft robotic muscles.

The decision to use soft robotic muscles was made due to their great properties as actuators. They are flexible and light; they expand in a high percentage in relation to their size; they have mechanical properties and the angle of deformation can be controlled (maximum almost 360 degrees). The challenge for using soft robotic muscles is finding the right proportion of the pressure needed to initiate movement against the resistance of the members and also finding the right kind of membrane stiffness which does not explode with the amount to actuation soft robotic muscle casted with ecoflex silicone pressure.

In this case we eliminated the thickness of the soft robotic muscle to zero. The thickness of the first layer remained the same (3mm) while the top layer is now 1mm. Different shores of silicone were also tested so as to test the behaviour of the soft robot muscle. We observed that the muscles were weak and did not have enough force to actuate; and with increase in pressure the soft muscles exploded.

- Place the wooden mold frame on a surface

- pour first layer of silicone

- apply a stencil on top when it gets dried,

- spray with hydrophobic spray

- remove the stencil

- pour second layer of silicone

Having studied the way how SMP can be activated and multiple actuators, we tested the properties of SMP as a smart material. This research included testing the polymer for its shape memory, tensility and mechanical performance. The Shape Memory Polymer, used in all our experiments, is the Veritex Composite.

In these experiments, SMP was tested for pulling and pushing weight. In both sets of experiments, the SMP was placed as a joint both in the inner and outer angles of the wooden sticks. In the case of small wooden sticks, the SMP performed as expected. When longer and heavier sticks were tested, the recovery of the SMP was not the same; there was a difference in the duration of recovery. In conclusion, the SMP can push weight quite easily, but when it comes to pull the same weight, it is not strong enough to regain 100% of its primary shape.

In these experiments, a combination of simple geometries was also tested by crossing wooden sticks with a double SMP joint. In all the three cases, the SMP regained a total recovery, though, there were some differences in recovery time as seen in the comments. It is found that gravity is a factor that affects the memory effect of the SMP; when the SMP has to pull weight against gravity, its performance is not efficient.

Following the complex scissors geometries, these experiments tested SMP’s placement in a row. We designed a strip from three pieces of polypropylene, a material light and flexible and the SMP pieces were placed on the valleys of the design. First, one SMP was tested, and later, multiple SMPs were placed in every valley in a variety of combinations rotating to x axis. The intention was to observe the deformation of the stripe which could lead us potentially to a surface organisation. The experiments were successful, as the SMP was strong enough to retain and push the stripe back to its initial position. The initial deformations were made both by hand and strings.

A step forward to the previous experiment is to translate a continuous strip to multiple modules. Now, the SMP acts not only as a joint but also as an independent component to a set geometry. During the experiment, the friction between the module and ground caused a great degree of resistance in SMP performance. When a smoother slide was achieved, the SMP recovered 100% to its initial position. However, the geometry was problematic as the modules were occasionally falling on the sides because of their weight and small width. That brought the need to create a supportive grid in two dimensions to support and keep the performing strips in place.

By testing the SMP in multiple geometries and directions, we became familiar with its mechanical properties:

- When it reaches its glass transition temperature its strength is low: it cannot carry weight more than 1 kg. On the other hand, when the SMP is at room temperature, it is an excellent retainer of weight and strength.

- Gravity is stronger than the pulling strength of the polymer: this means that the SMP can push towards gravity (because gravity is in favour of the movement) but it cannot pull weight against it. If different directions are combined, then the performance of the SMP is improved. As far as the activation is concerned, the nichrome wire is the most suitable one, as it offers precision and control of the heat and it is also possible to connect multiple SMPs together so that electricity can equally be distributed through a series or parallel circuit.

After our final experiments with geometries, which could potentially shape a responsive surface, we concluded that our research should focus on three main topics:

- Optimum SMP use as a joint

- Strong but controllable actuators

- Design focus on linear structures

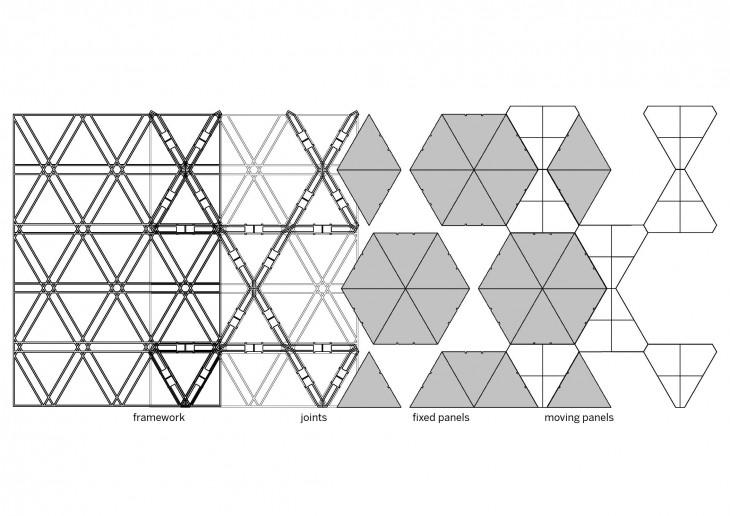

The final material system combines five different layers: the SMP coiled with the nichrome wire, the wood sticks, one polypropylene live hinge, one layer of silicone and the soft robotic muscle. They were joined together by revits, because of their ability to keep the layers together without moving (an issue we confronted with screws) as well as their light weight. The intention was to achieve the best performance of both the SMP and the soft robotic muscle at the same time, eliminating any resistence, keeping the parts together and connecting them with a supporting frame.

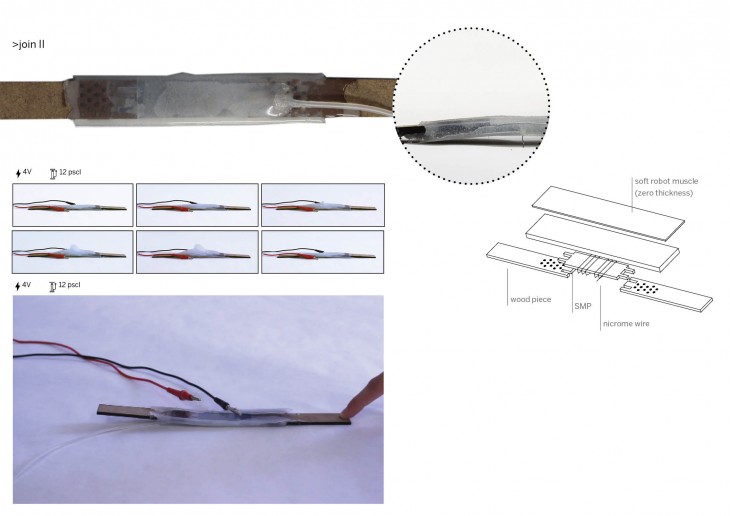

The design process concerns a study of organisation of space in grid. The objective is to enhance the wind from all possible directions. The way the joints are arranged in space would shape this system while their performance will release an organisation in adaptive panels. The gaps between them were filled with fixed components, while this system would be supported by a framework which will host the necessary technical equipment.

One of the triangular panels, that cover the grid, is fixed, while others move according to the wind flow, as explained before. The attached wooden sticks should have sufficient strength so that the muscle and the SMP can pull and carry. A panel of 50*50cm can support and lift the skin. The fixed panels are wooden (mdf 2.5mm) while the adaptives are supported from the joints and covered with silicone sheet. The performance of the panel concerns the opening of the angles rather than the sides of the triangular shape.

When wind comes from a certain direction, an interface provides the necessary data so that the joints are activated to open the panels. Each panel works individually but when connected in a larger system it permits the channelling of the wind in the whole area of the surface. The movement of the panels, open or stay closed, depends on the air and the electricity provided to the muscle and the SMP. If the SMP is heated then the muscle deforms it. If not, then the panel stays closed as the SMP retains its position no matter the soft robotic muscle activation.

With the use of Processing an interface was developed, which based on the location, will inform the system for the best solution to regulate the comfort zone through natural ventilation. Our intention is to develop a programmable skin where the user could also participate and express his own needs and desires. While the interface receives real time environmental data and proposes the optimum solution for temperature regulation, the user is able to change the results by introducing his own standards of comfort zone. The improvement of this interface can lead us to a complete calculation and control of environmental factors (natural light, rain collection etc)

This skin can be applied in different conditions and buildings; it can be used as a ceiling, as a facade or as a combination. Furthermore, with an improved structural adaptation, it can also stand on its own as a pavilion. The design allows adaptations as far as the scale of the panels and their position in space is concerned- multiple and different parameters can be applied depending on the use and the environmental conditions of specific locations on the map.

Project Credits

Response_able 2.0 is a project of IaaC, Institute for Advanced Architecture of Catalonia

developed at Master in Advanced Architecture 01 in Digital Matter – Intelligent Construction Research Line in 2015-2016 by:

Students: Nikolaos Argyros, Maria-Klairi Chartsia, Sameera Chukkapalli, Jakub Havlik

Faculty: Areti Markopoulou, assistants: Alexandre Dubor, Angelos Chronis