ONSITE_3D PRINTING

Using Robots

Bringing Robotics to the Construction Site to Manufacture the Future

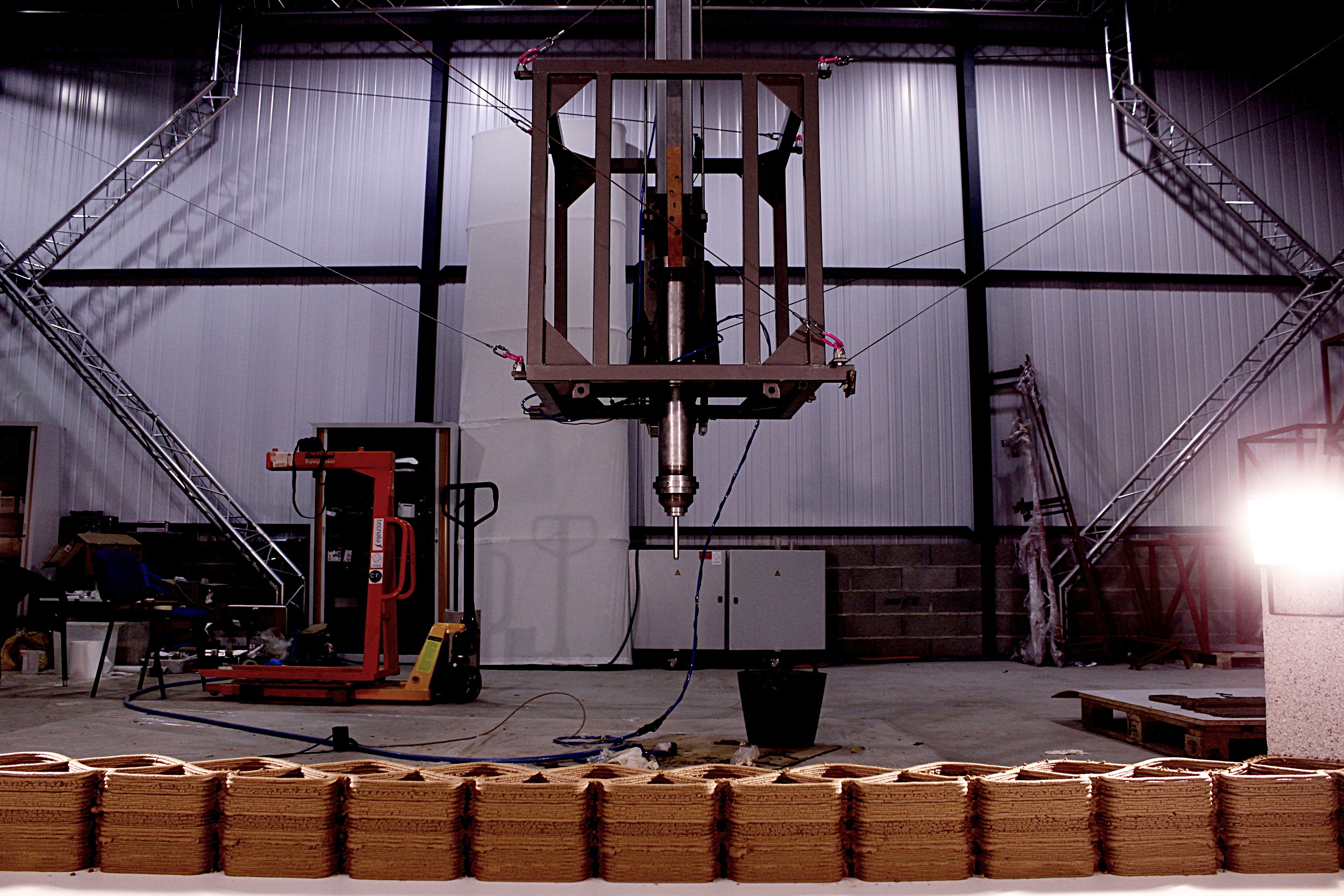

The project demonstrates the potential of additive manufacturing technology and robotics in designing sustainable low-cost buildings on site with natural materials.

This 3D Printing System can be used to 3D print both the large scale building elements and even small buildings from natural materials. This system includes the cable robot Cogiro with an integrated CNC control, which is able to automate the movement of the 3D extruder with precision. The printing can be executed in a very wide range of workspaces, and even directly on the construction site, by using cables operated by servo-controlled winches facilitating easy assembly, maintenance and reconfiguration.

The system integrates an extruder and a natural, biodegradable, recyclable material, based on the Pylos project. In addition, a custom script integrated in the CAD software allows easy translation of the complex forms of 3D design in the robotic trajectories.

The main advantages of using cable-driven robots for 3D printing in construction are:

- Having six degrees of freedom,

- Easy installation with simple foundation,

- Low maintenance,

- A high useful space to used space ratio, and

- Unit cost not dependant on the size of the installation.

Project Credits

Program Directors: Edouard Cabay, Alexandre Dubor.

Collaborators : Technalia, IAAC.

Researchers: Sameera Chukkappali, Iason Giraud, Abdullah Ibrahim, Raaghav Chentur Naagendran, Lidia Ratoi, Lili Tayefi ,Tanuj Thomas.